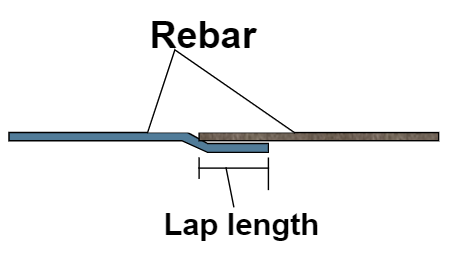

Column lapping length refers to the length of overlap between two reinforcing bars (rebars) used to construct concrete columns. Lapping is done to ensure the continuity of the reinforcement and to provide sufficient strength in the structural element. The lapping length is an important aspect of reinforced concrete structures to ensure that loads are effectively transferred and distributed.

The lapping length is influenced by various factors, including the type of structure, the diameter of the reinforcement bars, the grade of concrete, and the design specifications. In general, the lapping length is specified by structural engineers and is often expressed in terms of the number of bar diameters or as an absolute length.

Here are some key points regarding column lapping length:

Factors Influencing Lapping Length:

- Concrete Grade: The strength of the concrete influences the lapping length.

- Bar Diameter: Thicker rebars may require a longer lapping length.

- Structural Design: The design specifications provided by structural engineers dictate the lapping requirements.

Common Practices:

- The lapping length is often expressed as a multiple of the diameter of the reinforcement bars. For example, it might be specified as 40 times the diameter of the bar.

- In some cases, a minimum absolute lapping length is specified regardless of the diameter of the bars.

Placement of Laps:

- Lapping is typically done at points where the bending moments are relatively low, such as at the mid-height of a column.

- Laps are usually staggered in different sections of the column to ensure uniform distribution of reinforcement.

Development Length:

- The concept of development length is related to lapping length. It refers to the length of the bar required to develop its full strength.

- In cases where lapping is not feasible or practical, alternative methods such as mechanical splicing may be used to achieve the required development length.

Code Requirements:

- National and international building codes, such as those provided by the American Concrete Institute (ACI) or the Indian Standard (IS), often specify guidelines for lapping lengths based on structural considerations.

Lapping in Reinforcement:

Lapping is a technique used in construction, particularly in reinforced concrete structures, where two lengths of reinforcing bars (rebars) are overlapped to create a continuous and effective transfer of loads. This overlap ensures the structural integrity of the construction by allowing the load to be distributed smoothly from one bar to another.

Column Lapping Length:

Column lapping length specifically refers to the length of overlap between two vertical reinforcement bars in a column. It is a critical parameter in ensuring that the column can resist the loads it is subjected to and maintain its strength. The lapping length for columns is influenced by factors such as the type of structure, concrete grade, column dimensions, and the diameter of the reinforcing bars.

Lapping Length Formula:

The formula for calculating the lapping length can vary based on design codes and specifications. However, a common approach is to express the lapping length as a multiple of the diameter of the reinforcing bars. The formula is often given as:

In general, lap length is 50d which means 50 times the bar diameter

Lap Length = 50 x D

Where,

D = diameter of the reinforcement bars

Here, the development length is the length required for the bar to develop its full strength, and the multiplying factor is typically specified in design codes.

Zone in Lapping:

In the context of column lapping, the term “zone” usually refers to the vertical height along the length of the column where lapping is allowed or recommended. Different zones within a column may have specific requirements for lapping lengths based on factors such as the expected stress and load distribution. For example, lower zones of a column, where higher loads are anticipated, may require longer lapping lengths.

It’s important to note that specific lapping length formulas and zone considerations can vary depending on local building codes, design standards (such as those provided by organizations like ACI or IS), and the structural engineer’s specifications for a particular project. Engineers determine lapping requirements based on factors like structural analysis, material properties, and the desired safety margins for the specific structure under consideration. Always consult with a qualified structural engineer and refer to the applicable building codes for accurate and project-specific information.

Nicely provided support in its simplicity.